- Home

- About us

- Products

- Continuous Magnetron coating Production Line

- Vacuum Coating Equipment

- Large Multi-arc ion vacuum coating equipment

- Vacuum Evaporation Coating Equipment

- Vacuum multi-arc ion coating equipment

- Vacuum magnetron sputtering coating equipment

- Vacuum intermediate frequency coating equipment

- DLC & Tools and Mould Vacuum coating equipment

- Coating Service

- PVD Vacuum System for Glass Products

- Accessories

- Cleaning Machines

- Ungrouped

- Faqs

- News

- Certificate

- Contact us

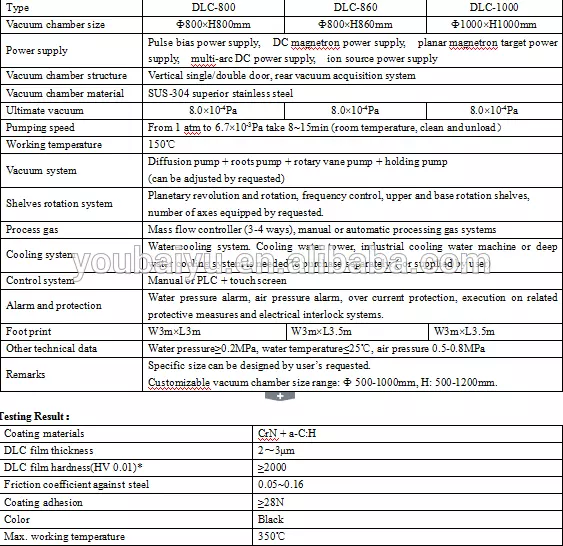

DLC vacuum coating machine

- FOB Price

US $150000.001 - 1 piece

- group name

- DLC & Tools and Mould Vacuum coating equipment

- Min Order

- 1 piece

- brand name

- UBU PVD coating machines Manufacturer

- model

- DLC vacuum coating machine

- Nearest port for product export

- 青岛

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T

- update time

- Fri, 18 Oct 2019 08:42:33 GMT

Paramtents

progressing:60 day sample progressing:15 day

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Diamondlike carbon (DLC) film which has the advantages of stable quality, corrosion resistance, wear resistance, low coefficient of friction, super durable, and strong adhesion with the substrate, is widely used in coating precision semiconductor mold, medical instruments & implants, higher thermal components, stainless steel forming stamping molds and also the film surface-hardened of engine parts, sliding sealing parts, non-ferrous metal cutting tools, measuring tools, wear parts (bearings, plunger, beryllium copper, aluminum) , aerospace and textile equipment and parts.

Diamondlike carbon (DLC) film which has the advantages of stable quality, corrosion resistance, wear resistance, low coefficient of friction, super durable, and strong adhesion with the substrate, is widely used in coating precision semiconductor mold, medical instruments & implants, higher thermal components, stainless steel forming stamping molds and also the film surface-hardened of engine parts, sliding sealing parts, non-ferrous metal cutting tools, measuring tools, wear parts (bearings, plunger, beryllium copper, aluminum) , aerospace and textile equipment and parts.